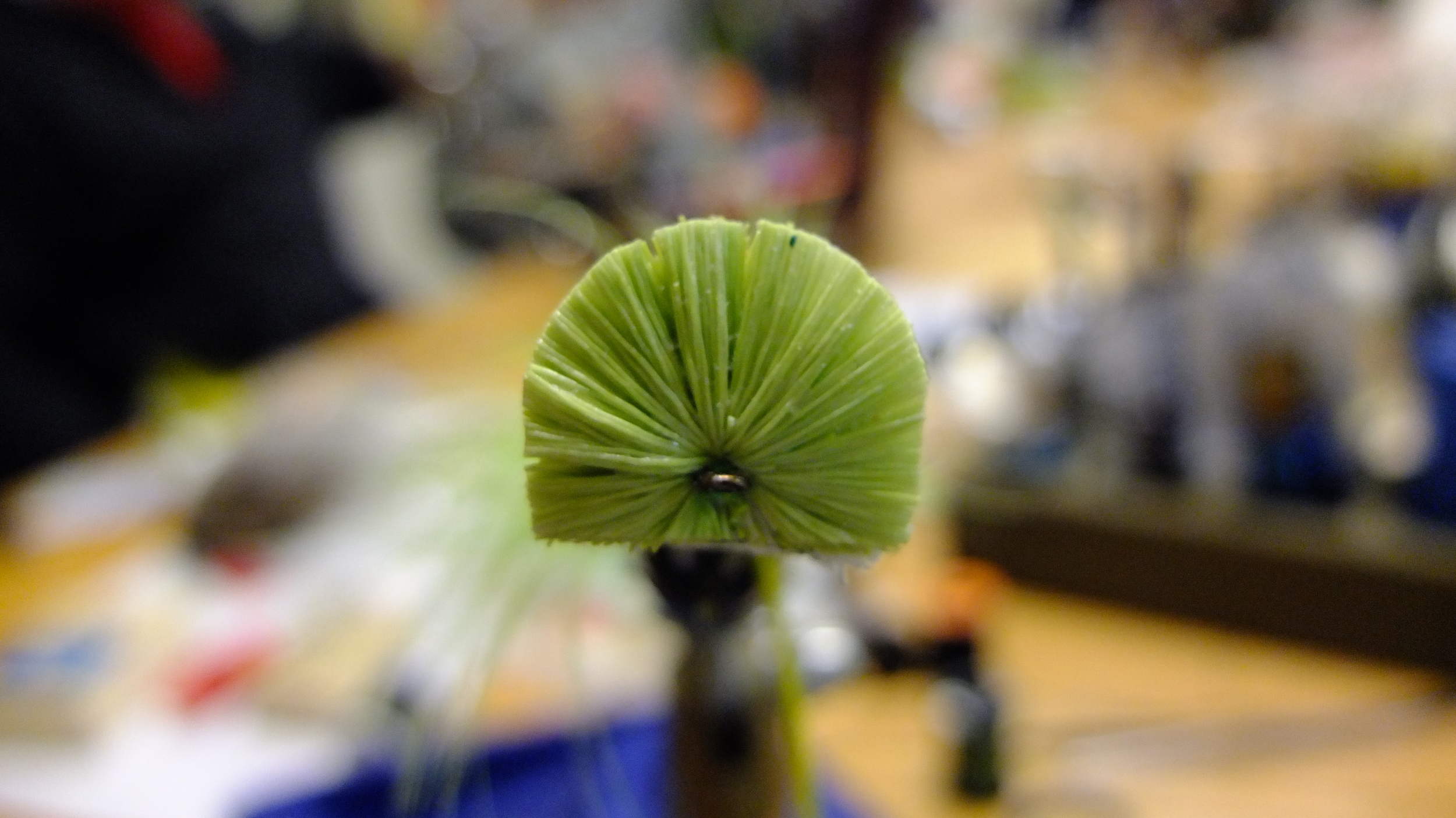

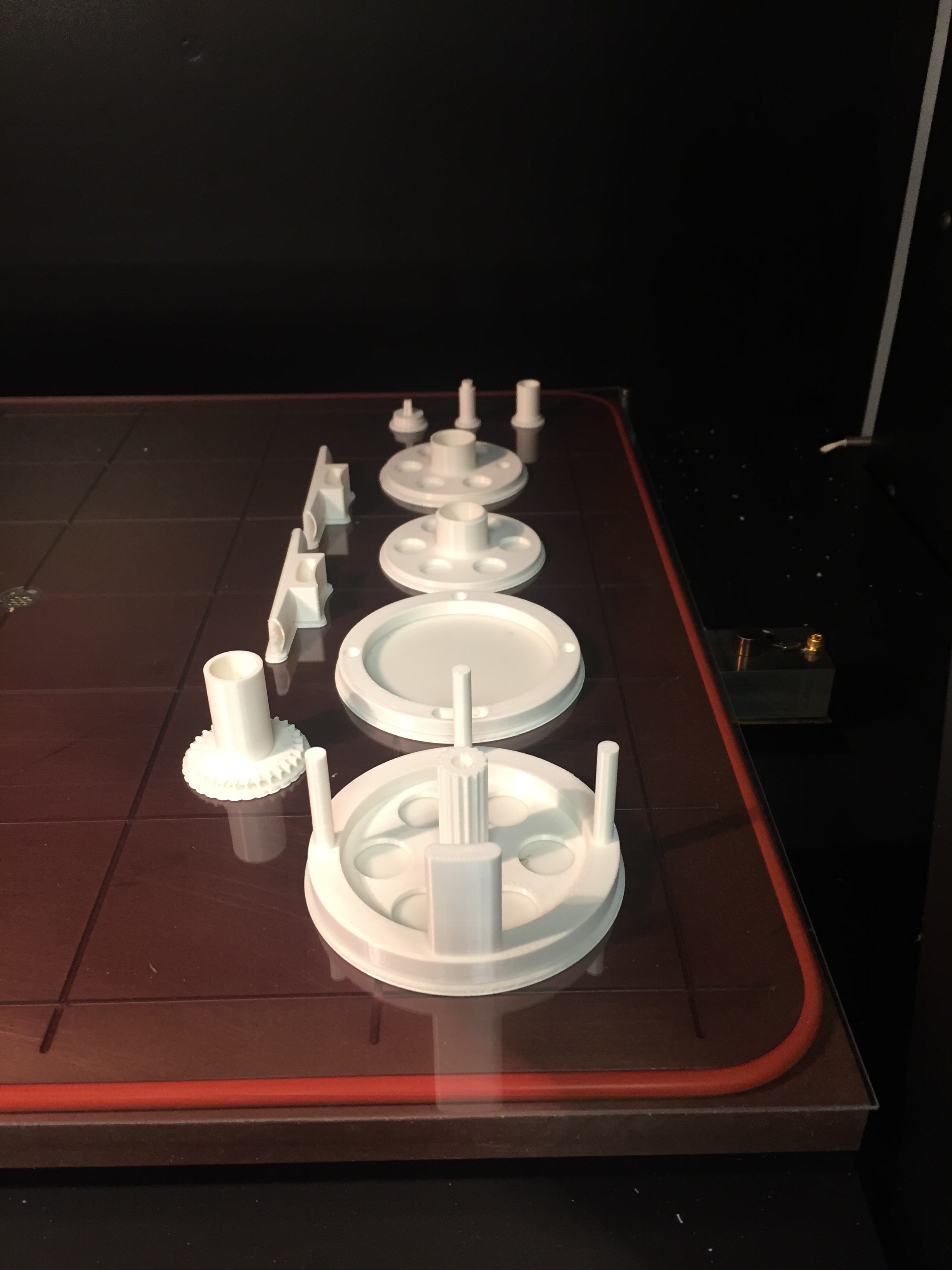

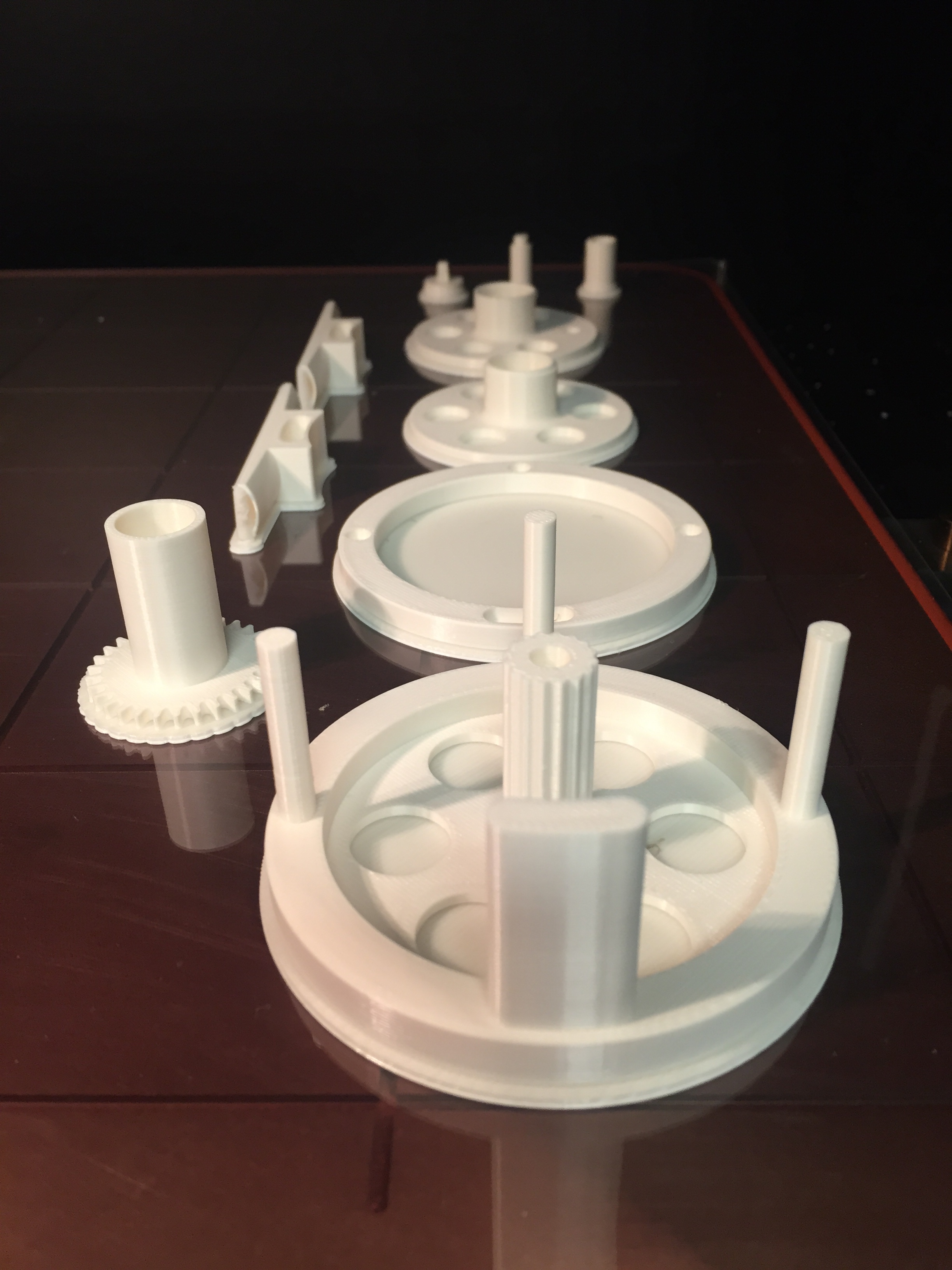

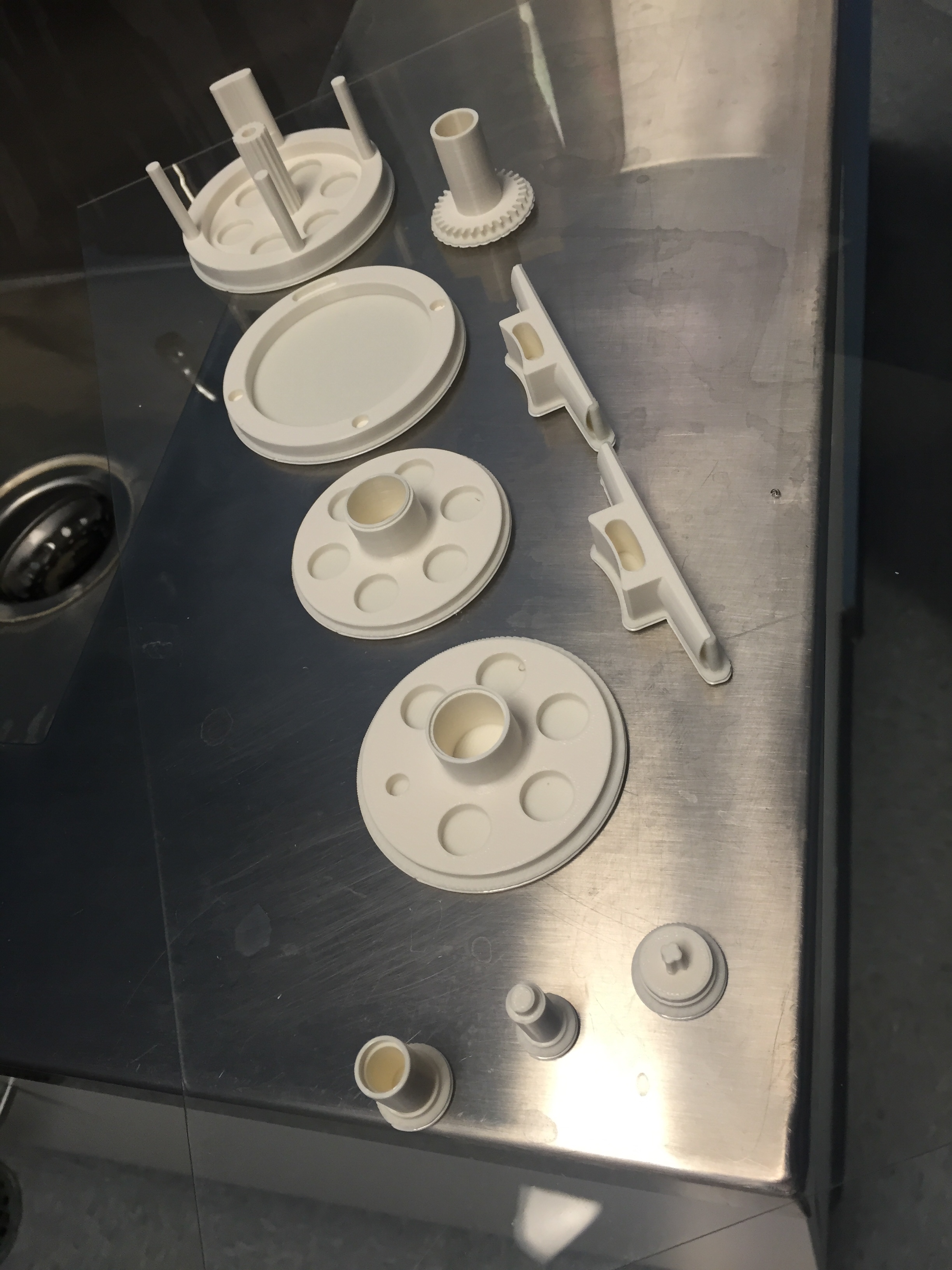

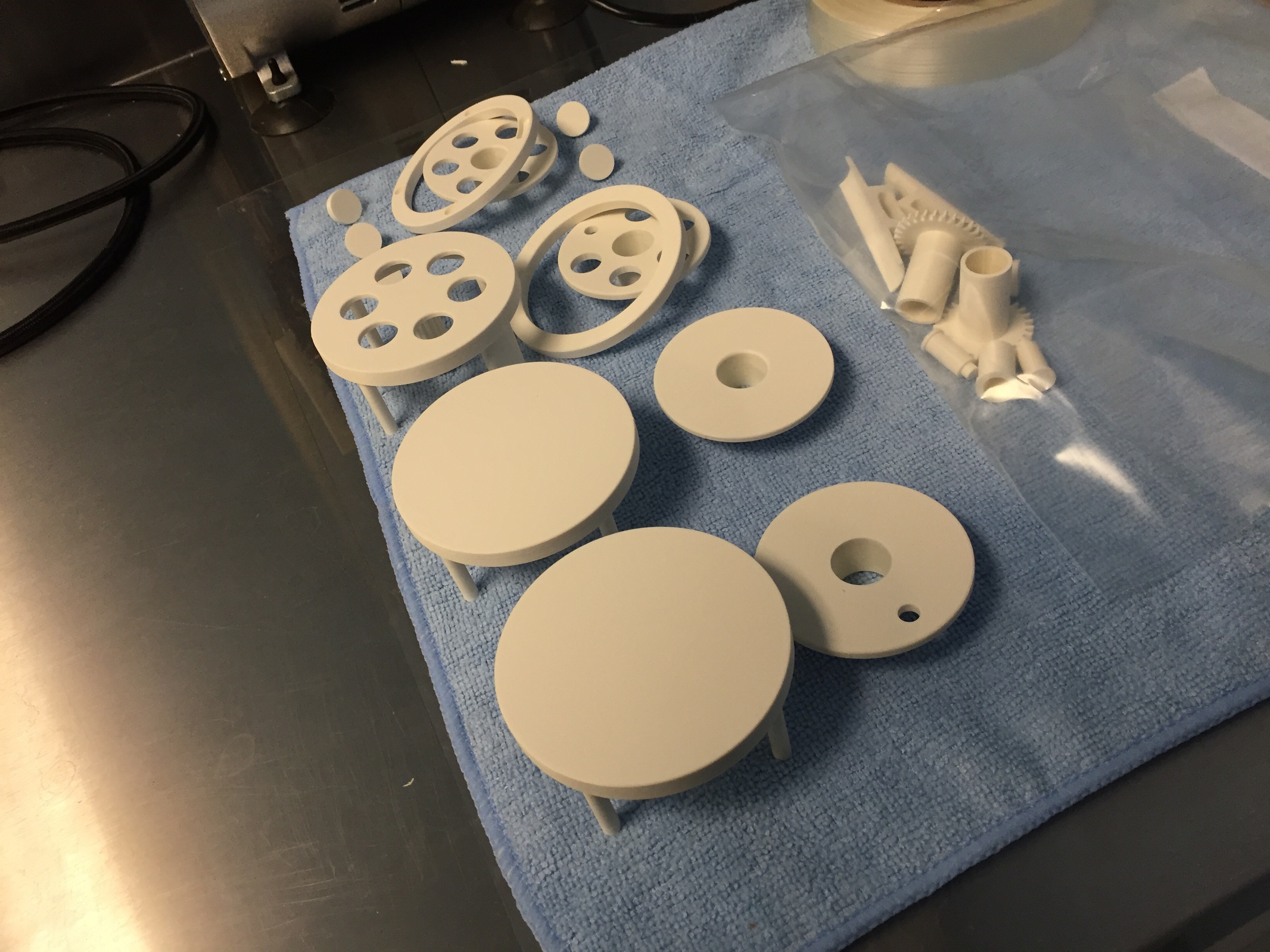

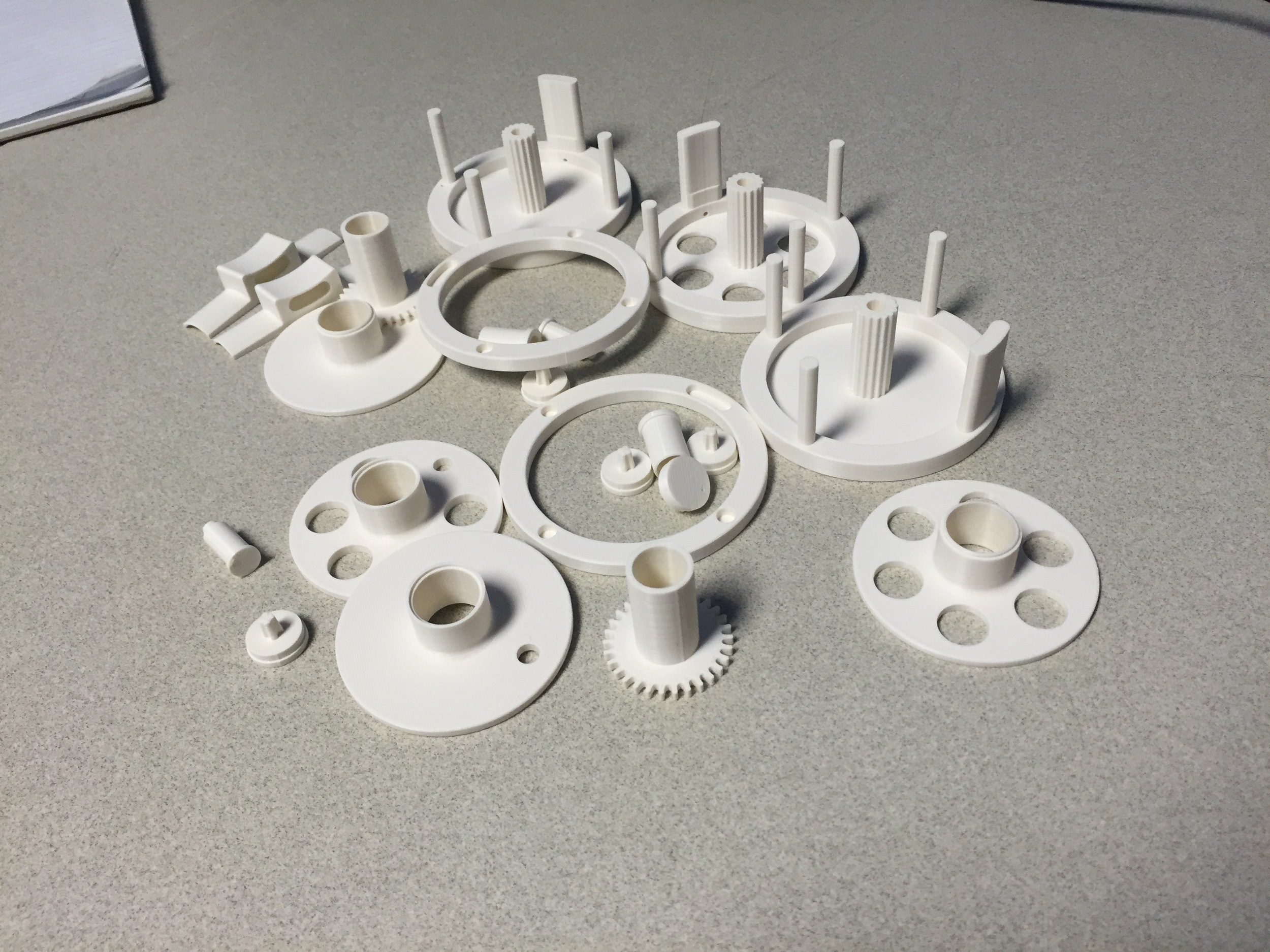

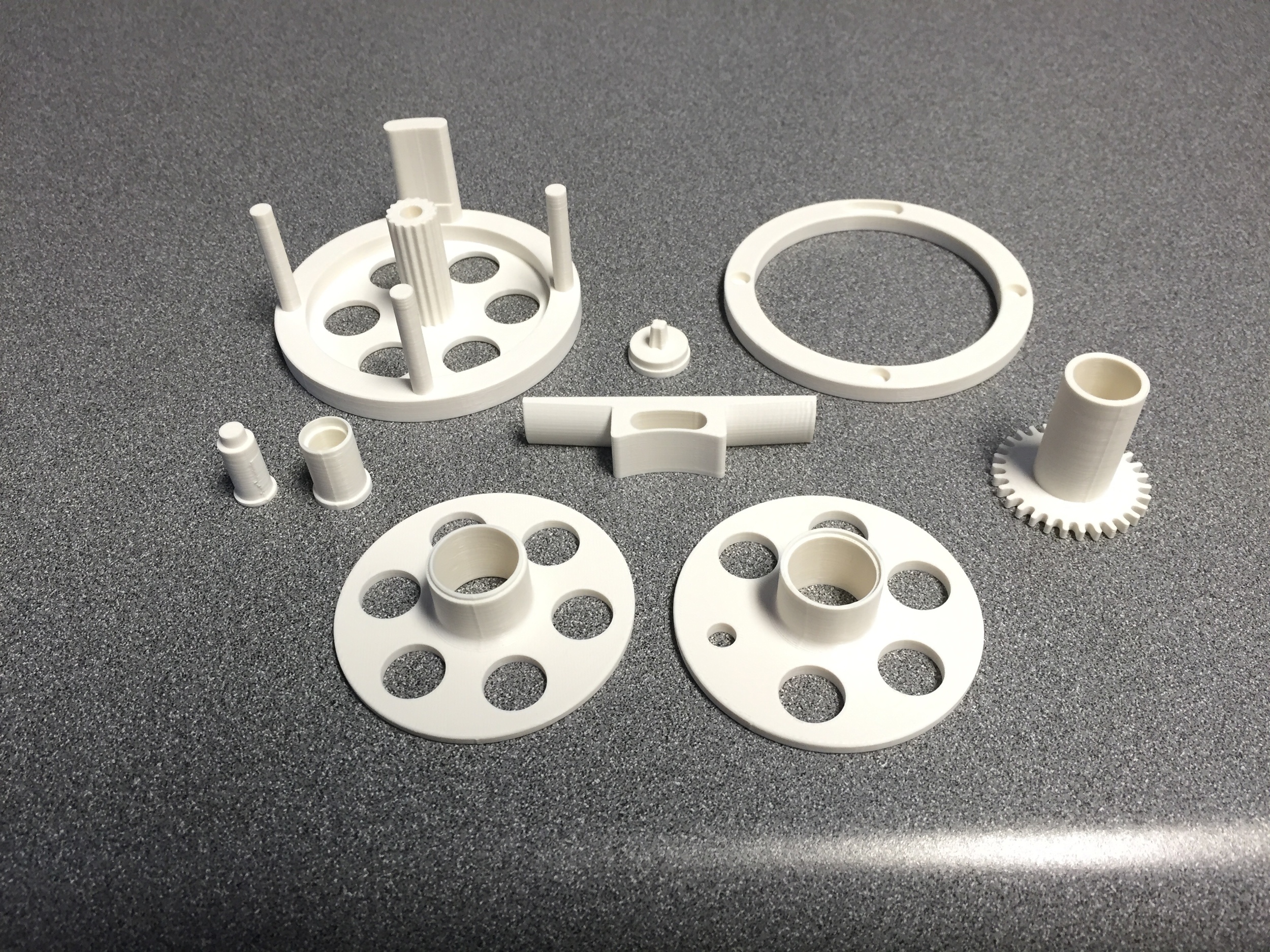

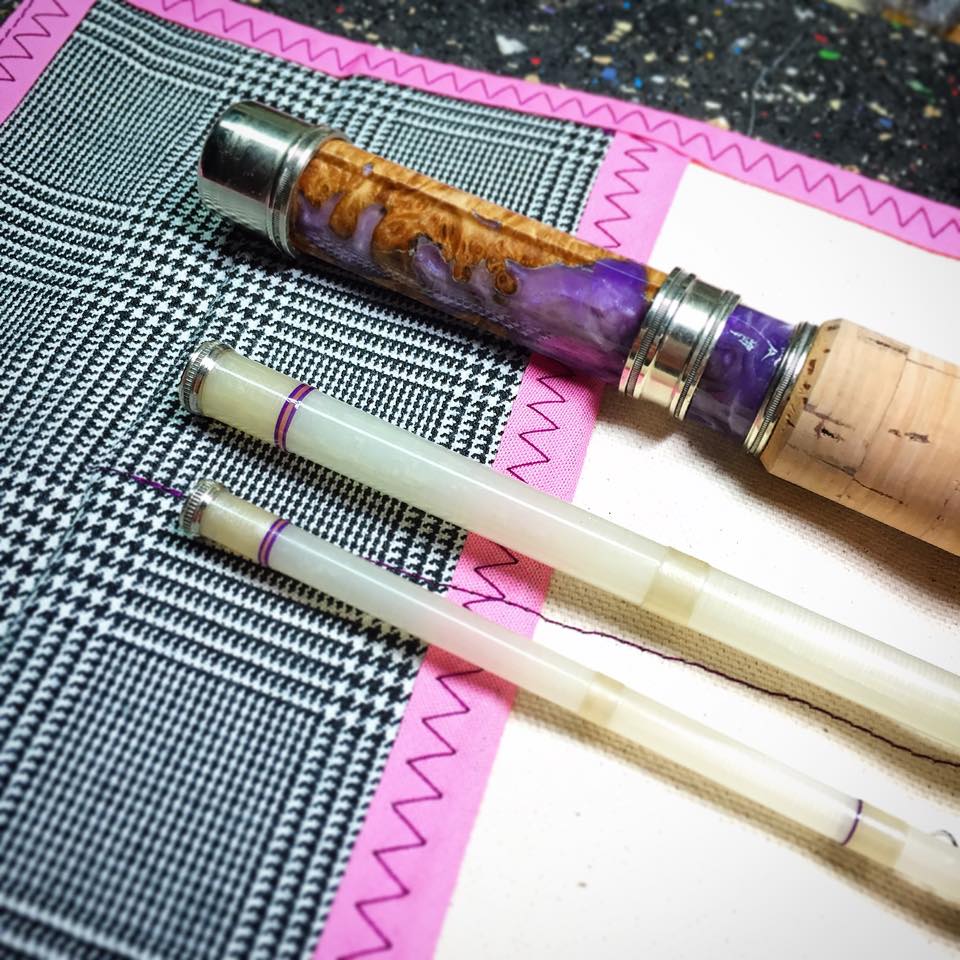

So he sat and tied. He wasn’t very good but he was earnest. And as he’d say, “I was hooked.” Cory continued to improve and was very interested in deer hair bugs. Like anyone seeking to improve, he found a teacher and took lessons from the master: Chris Helms. From his sessions with Chris, Cory continued to improve and his flies, as you can see from the photos, are what we all aspire to, tight, well packed and durable hair bugs. Beautiful can also be applied to them.

Cory has from time to time, given me a fly or two and yes, I have fished them. I know, usually most people decorate their boxes with hair poppers and divers but when they hit the water, they pull out the foam ones . But hair bugs are great in the water, they leave a lot of bubbles, are usually light and cast well and besides, they just look cool. And tying deer hair is a skill set that anyone wanting to tie more than just a woolly bugger or clouser minnow should learn.

And now is your chance. At the end of the month, Saturday, March 28th at 9:00 at Coren’s Rod and Reel, 6001 N Nina Ave, Chicago, IL 60631 · (773) 631-5202, you can take a free deer hair seminar with Cory.

You have to have your own vise and tools and a spool of GSP. There will be some available for purchase but I suggest you get a spool and bring it along. Also if you have deer hair suitable for spinning, bring that as well. While this is a free seminar, I would ask that at the end of it you toss a couple of bucks into the kitty for Cory as he puts a lot of time, effort as well as supplying materials for this seminar.

Chris Helms passed away in November of 2014 but his student, Cory, continues the tradition of tying deer hair bugs. I am certain that Chris would say of Cory, “Well done my student, well done.”

So if you’re interested in spinning, stacking, packing and trimming deer hair to make poppers, sliders, and all kinds of interestingly shaped flies. Then come this Saturday. Space is somewhat limited so you might want to bring a folding chair.

See you there!

Here’s that info one more time:

Location: Coren’s Rod and Reel, 6001 N Nina Ave, Chicago, IL 60631

Time and Date: Saturday, March 28th at 9:00

Phone: (773) 631-5202